Gallery

Full Description

Customer Reviews

Workshop and Scholarship Overview. Rob Cosman Woodworking is offering 12 fully funded scholarships for Purple Heart Project alumni to attend the Intermediate Drawer Making Workshop on 6-11 October 2025. This workshop is a 6-day intensive workshop that focuses on drawer and cabinet making (see below for workshop details). Scholarship selections are a competitive selection made by Rob Cosman based on the results of a submitted drawer project (See below for details). Hosted at Rob's Workshop located in Grand Bay, New Brunswick, Canada. If after reading through the information below, you have any questions about this workshop or this application project please email your questions to: support@robcosman.com.

Scholarships. Rob Cosman is offering 12 scholarships for this workshop. A scholarship pays for:

- Air and ground transportation to and from Rob's Workshop.

- Lodging while at the workshop.

- Tuition and materials for the workshop.

- A lunch meal daily during the workshop. (Selectees are responsible for providing their own breakfast and dinner meals)

How to Qualify for a Scholarship. To be considered for a scholarship, applicants must meet the below two prerequisites:

- Applicants must be a Purple Heart Project alumni who has attended a Rob Cosman Training the Hand Workshop prior to 6 October 2025 and

- Applicants must purchase this scholarship application project, build the project, and return the completed project back to Rob Cosman Woodworking using the enclosed pre-paid return UPS shipping label no later than 30 June 2025.

Application Project Instructions (See video posted with this product).

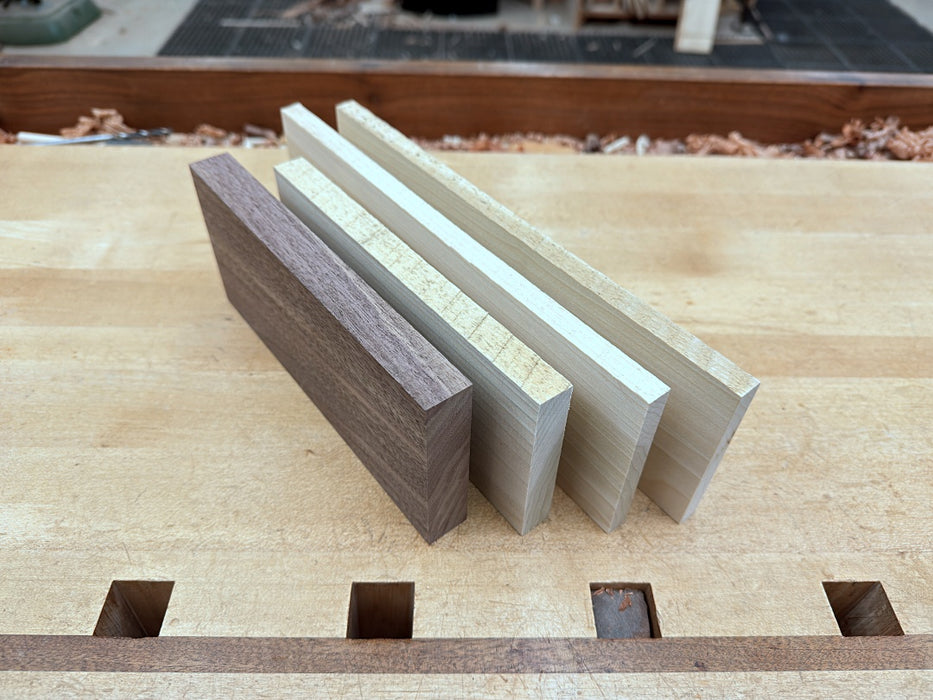

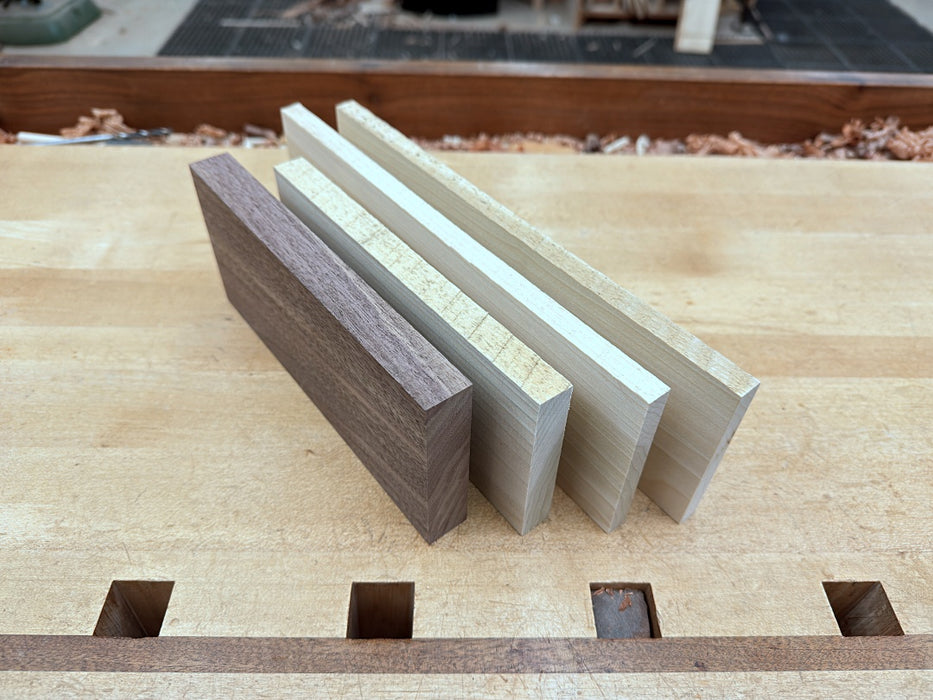

- The application project includes four pieces of partially milled wood needed to construct the basic drawer box, project plans (DOWNLOAD HERE), a prepaid return UPS shipping label, and the shipping box.

- Using hand and/or power tools, applicants must do the final milling to the wood sizes specified in the project plans.

- Construct a drawer box (without a bottom) consisting of half-blind dovetails on the drawer front and through dovetails on the drawer back, to the size specifications in the drawer plans.

- The drawer box must be assembled, glued, and surface planed so it is ready for a finish.

- Once completed, pack the drawer box into the original shipping box, affix the pre-paid UPS shipping label, drop the box off at any UPS shipping location no later than 30 June 2025.

Scholarship Selctions. Rob Cosman will review and select the 12 best submitted projects as the Scholarship selectees. Scholarship Selectees will be notified by phone no later than 31 July 2025

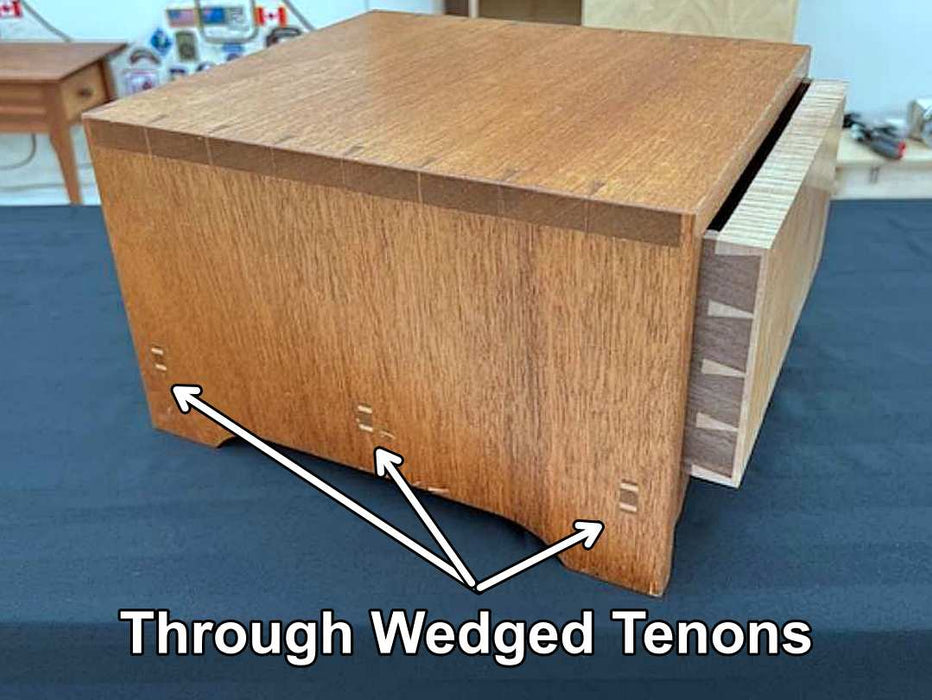

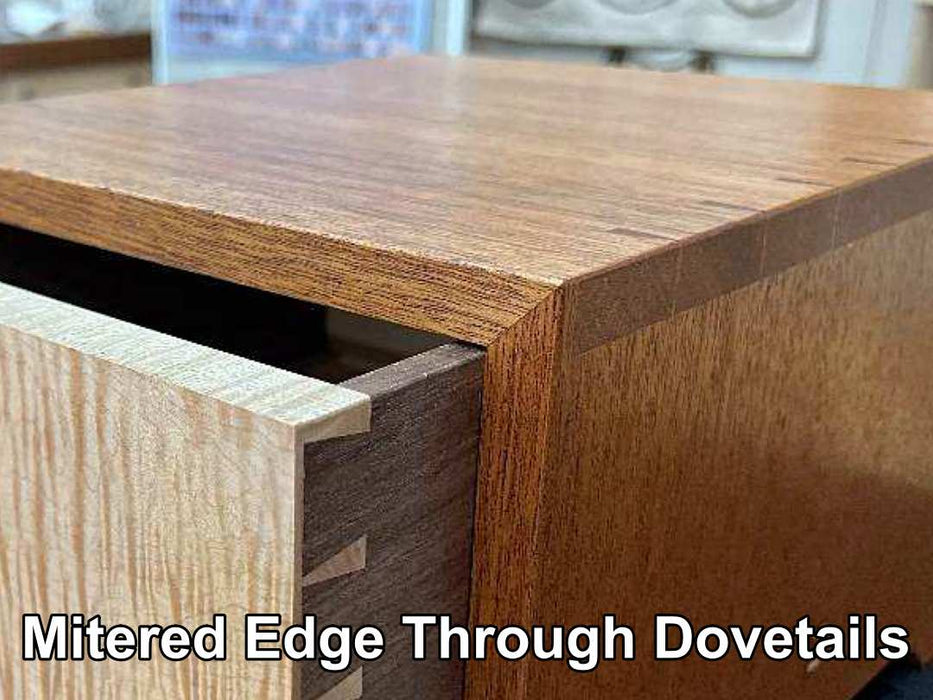

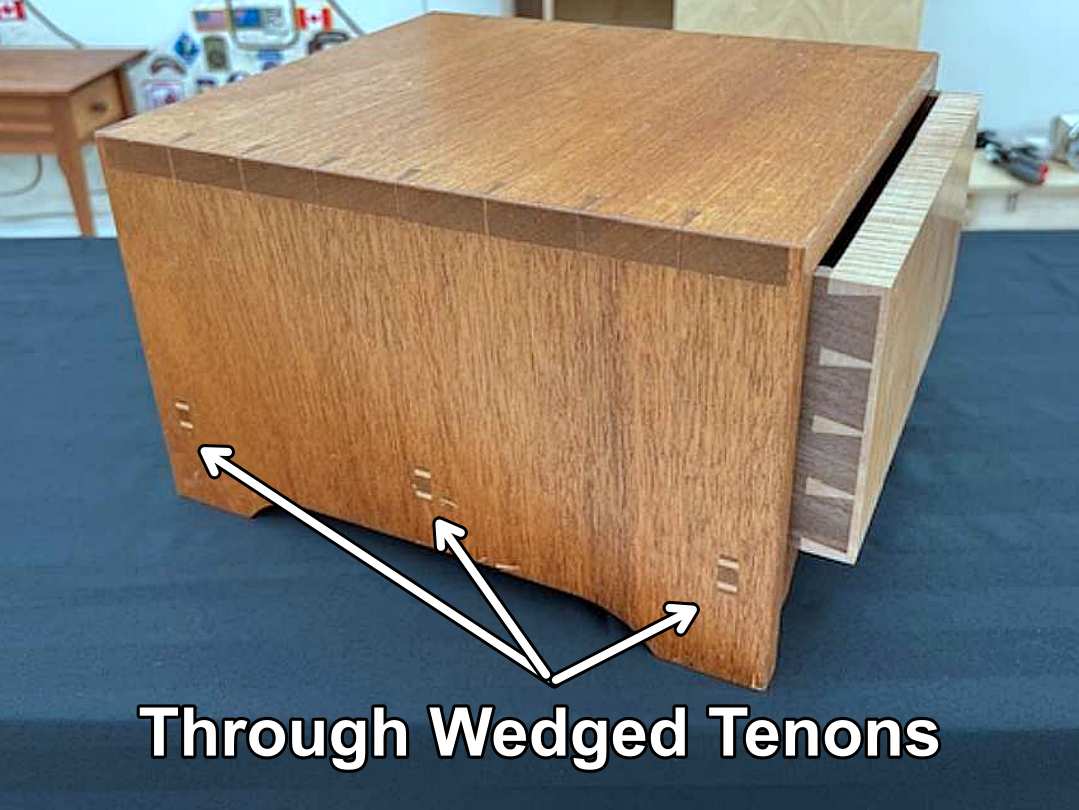

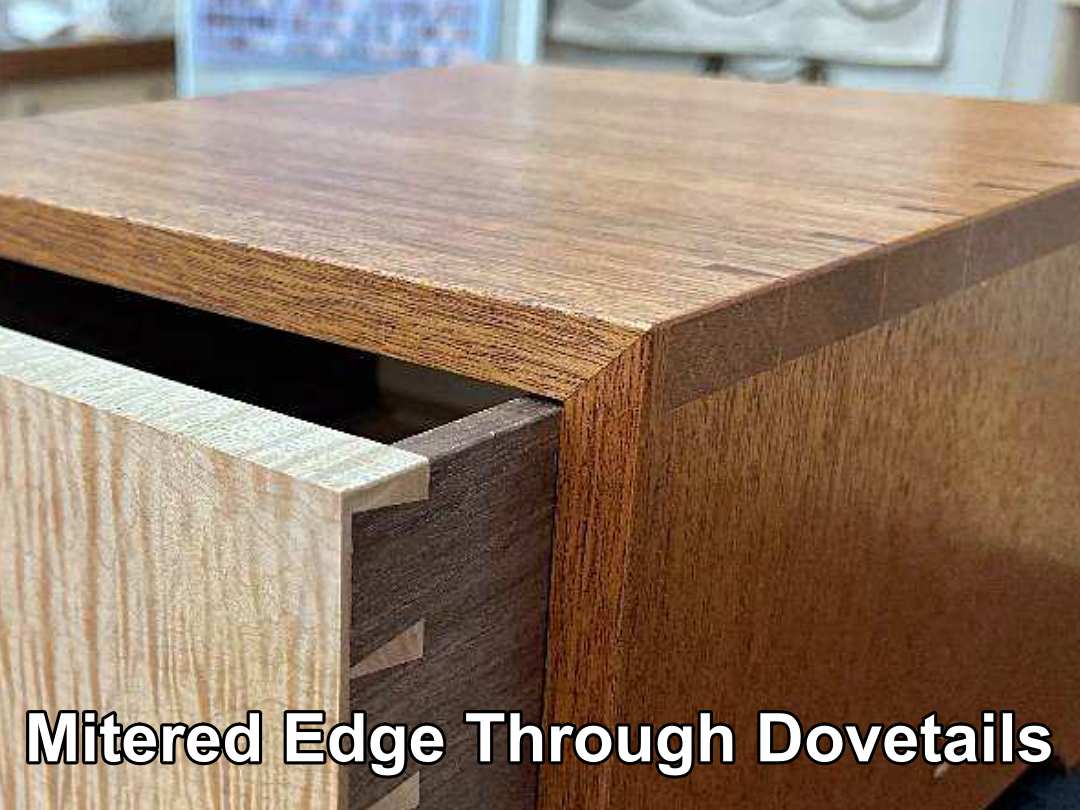

Workshop Details. The intermediate Drawer Making Workshop is a project-based learning experience (see pictures in the gallery). Rob teaches his traditional approaches to drawer making and case construction. Learning the art of drawer building and fitting is the primary focus of this workshop with precision case construction a very close second. The learning goal is that by the end of the week you can construct a complex and accurate case using dovetails, dadoes, through wedged tenons, and achieve a piston fit drawer!

Workshop Drawer Project Details. The project built during the actual workshop is a simple but technically advanced single drawer case of Rob's design. The overall case dimensions are 11-5/16 inches (289mm) wide x 12-11/16 inches (317mm) long x 7-7/8 inches (200mm) tall. The perfect size for construction at your workbench and to get on an airplane to take home.

We provide all the lumber for the case and drawer. Students have a choice of walnut, cherry, or maple hardwood for the case and the drawer front. Poplar is the secondary wood provided. The lumber comes already machine milled straight, planed to thickness, and has one edge jointed. Using all hand tools, students cut their lumber to size, six square the boards, and surface finish their wood.

The case's top is attached to the sides with through dovetails with a miter edge front. The case's bottom is let into a shallow dados and secured to the sides with through wedged tenons. The cabinet back is a solid panel that floats in grooves cut into the sides and top of the case.

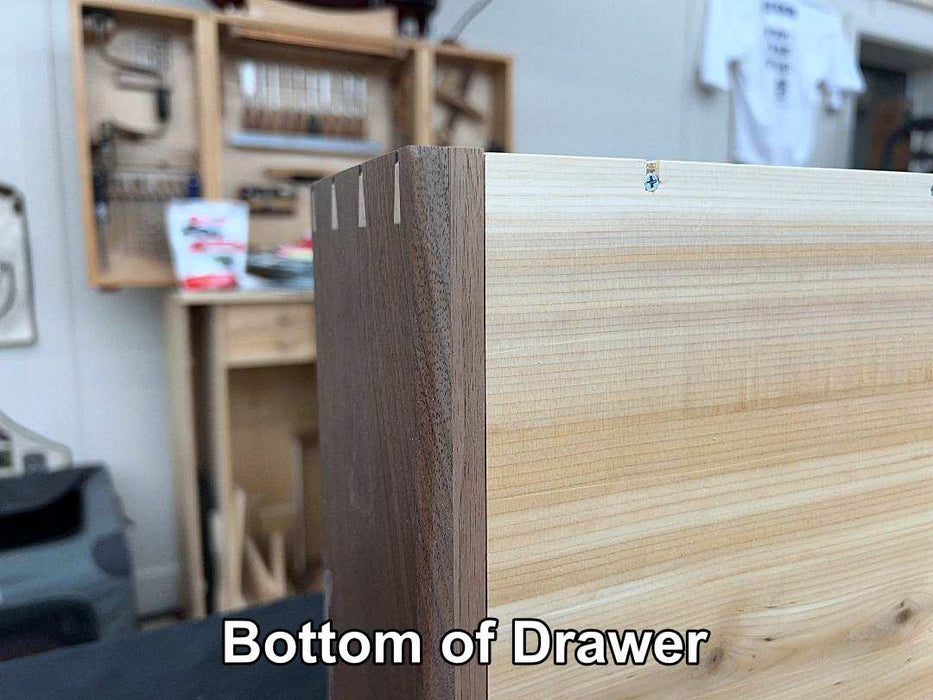

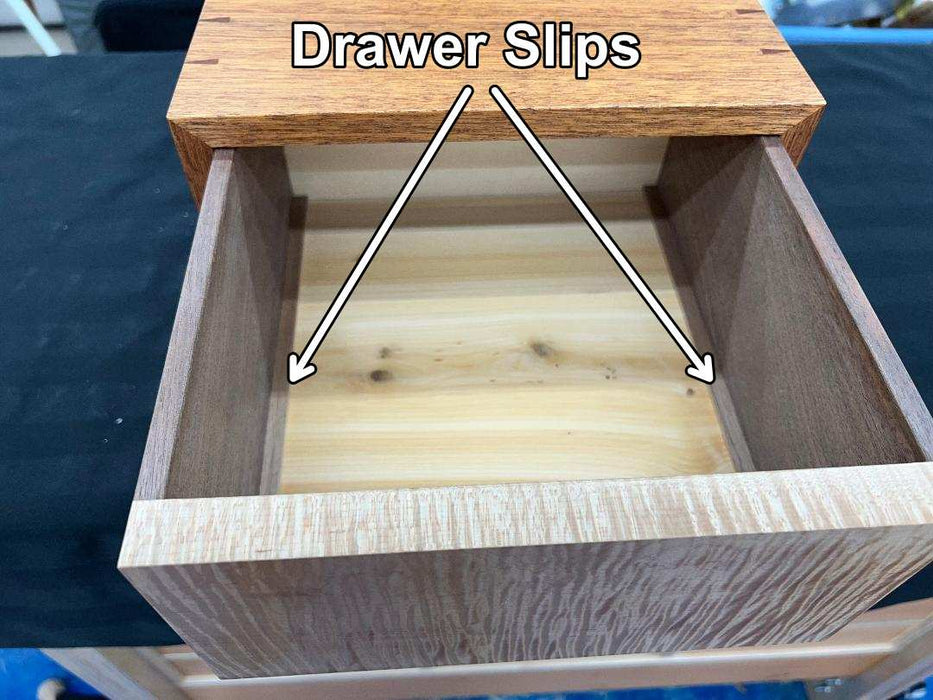

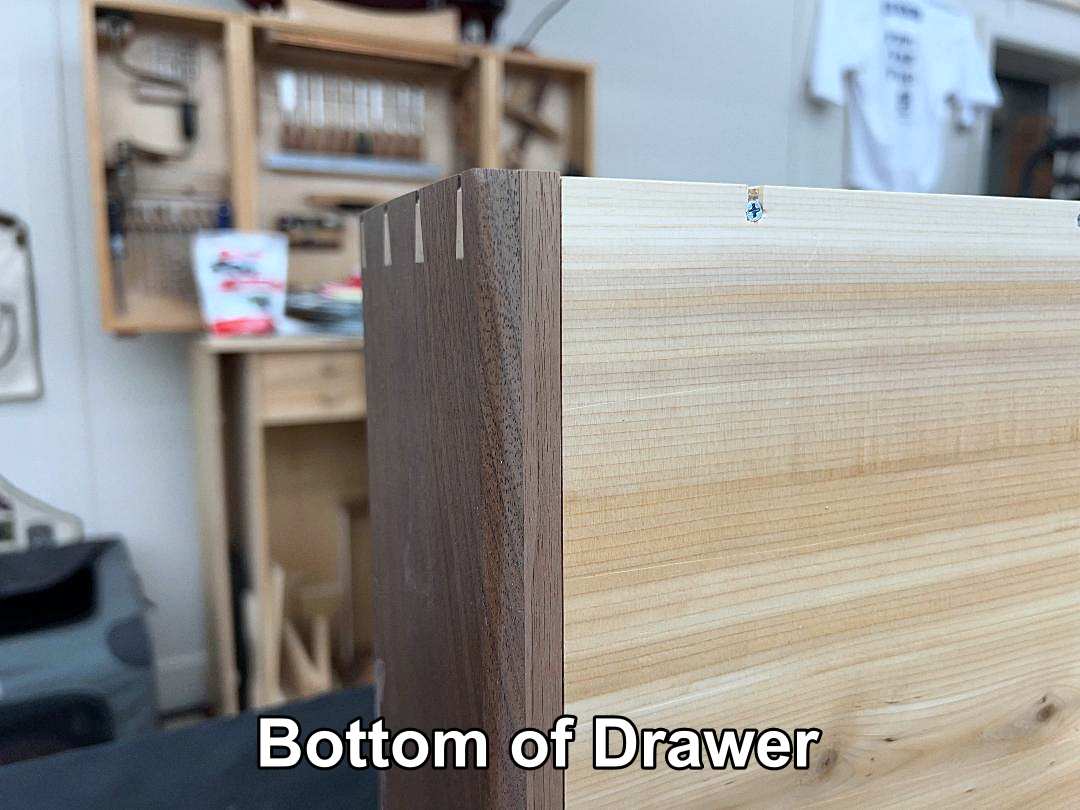

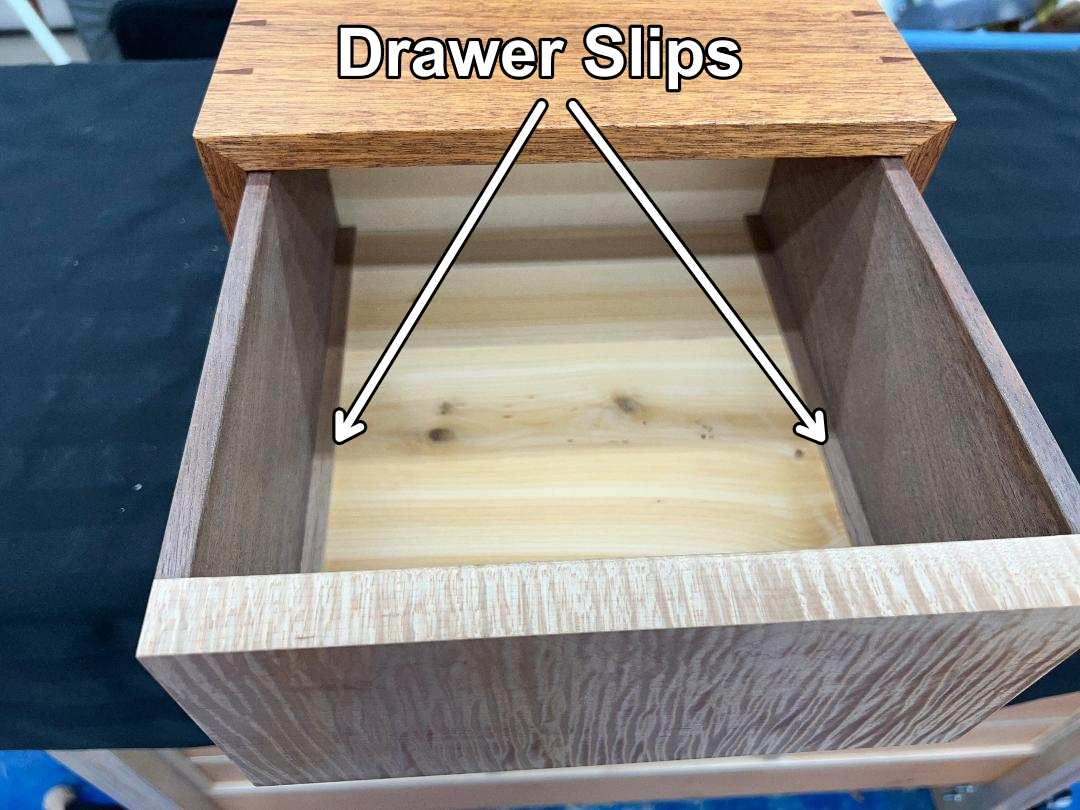

A traditional drawer is constructed with the front joined to the sides with half-blind dovetails and the back joined to the sides with through dovetails. Drawer slips are added to the sides and a solid pine bottom panel is tongue and grooved into into the drawer front, half lapped on the back and butt jointed on the sides. The bottom sits in a groove in the slips. The drawer is precisely fit to the case opening so as to achieve a "piston-fit."

Woodworking Skills Covered: This workshop builds upon the hand tool skills taught in the Training the Hand Workshop and introduces new skills. The new skills introduced are:

- Drawer-making and fitting.

- Case construction.

- Through wedged tenons.

- Hand cut dados.

- Miter edge dovetails.

- Drawer slips.

Workshop Schedule. This workshop runs daily from 07:30 am to 10:00pm. Please have breakfast before you arrive at the workshop. We serve a hearty lunch meal around noon. Bring your own meal for supper or dine after the end of the day. On Saturday, instruction ends at 7:00 pm, then we clean up and re-organize the workshop, pack-up tools, and depart.

This is a full week of intense woodworking that will take your drawer and cabinet making skills to the next level. We guarantee it will be money well spent and you will go home a better hand tool woodworker.

Workshop Location. The Workshop: Intermediate Drawer Making is held in Rob's personal workshop which is located at 275 River Valley Drive, Grand Bay, New Brunswick, E5K 1A7, Canada. The nearest large city is Saint John, New Brunswick Canada, approximately 15 minutes east of Rob's workshop. The nearest large U.S. city is Bangor, Maine, located approximately three hours south of Rob's workshop.

Initial Meet-and-Greet. We have an initial meet-and-greet and BBQ at Rob's Workshop for all students who can make it on the Sunday before the workshop begins at 7:00-9:00 p.m. (Atlantic Time). This is so you can see the facility; claim your workbench; drop-off any tools you brought; eat some "Frick'n good BBQ", and meet everybody. If you cannot make the Sunday meet-and-greet please let us know and we will see you on Monday morning. As the workshop date gets closer we will email you with more details on this "meet-and-greet."

Required Tools. Each student is expected to bring their own tools to the workshop, unless they are renting a tool kit from us. Click on the red button below to see the list of required and optional tools, learn about renting tools, and other tool information.

Medical Coverage. Students are responsible for arranging and paying for any medical services required while attending the workshop. While the risk of injury or illness at our workshop is very low, injuries and illness have and do occur. While we can handle minor cuts and scrapes, we highly recommend non-Canadians purchase short-term visitor / tourist insurance for their visit to Canada. There are numerous companies that offer this coverage. We do not provide any recommendations. We recommend doing an internet search for, "Tourist medical coverage in Canada." That will return numerous results.

Basic Requirements to Enter Canada. Entry into Canada is solely determined by Canada Border Services Agency (CBSA) officials in accordance with Canadian law. We have had students that have had difficulties entering and one or two have even been denied entry into Canada. We recommend you click on the red button below and carefully read the the requirements for entry into Canada.