Gallery

Full Description

Customer Reviews

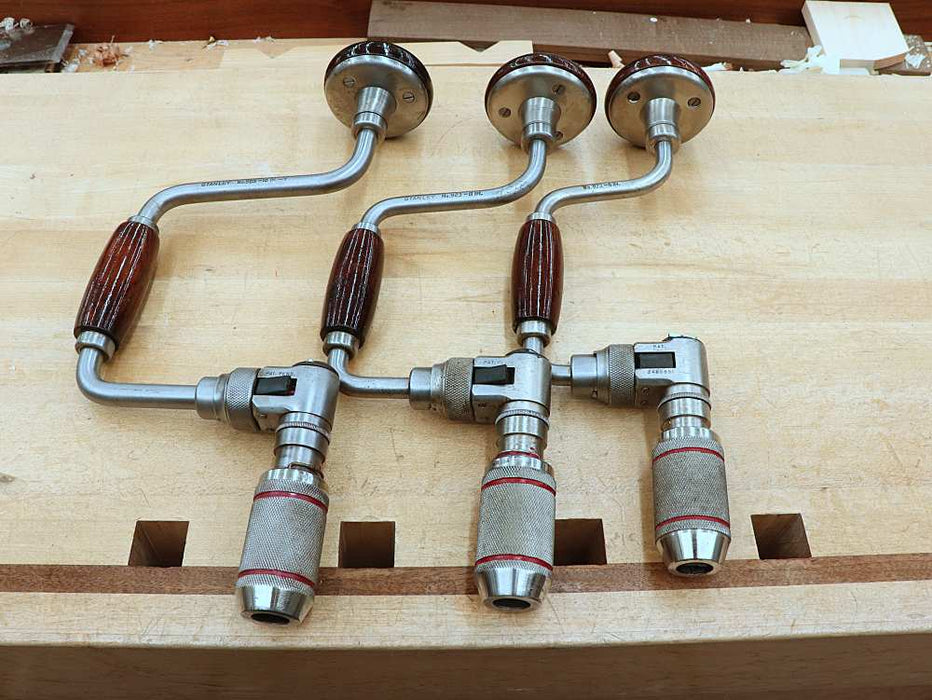

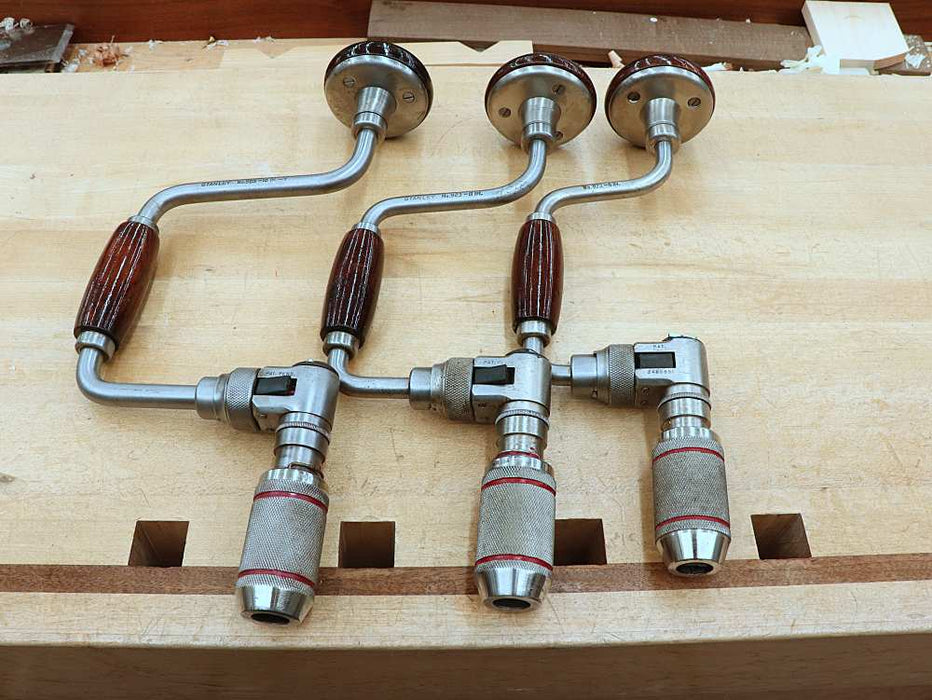

This fully restored, and rare, Stanly 923 brace set includes the three brace sizes that Stanley primarily made: 6, 8, and 10 inch throws. Craftsmen in the day would pick the brace needed for the job. The 6 inch brace for rapid drilling of small holes in softer woods. The 10 inch brace for creating high torque needed to drill large holes or when drilling very hardwood. The 8 inch brace was the Jack of all trades brace used for drilling middle sized holes in soft to medium hard wood

Most modern braces made today do not come close to the quality of these vintage braces made before the 1960's. Fortunately, vintage braces are plentiful, but they have been sitting around unused and unmaintained for 40 years or more and need more that just an exterior cleaning.

Our braces are professionally restored to a better than new condition by Ernie Stephenson, our master brace craftsman. Watch the accompanying video to see Ernie explain how he restores each brace.

Brand: Stanley

Model: 923

Chuck: Improved Barber Bell

Swing: 6, 8 ,and 10 inches

Ernie's 6 Point Brace Restoration Process:

- BREAKDOWN & INSPECTION: Brace is inspected for over all condition. If it is too badly rusted or damaged for restoration the brace is rejected.

- QUILL BEARINGS REPLACED. All quills (hand grip) bearings are sized, replaced, and repacked with grease. If the bearing race has slipped too far forward, it is tapped back into place.

- FRAME STRIPPED AND CLEANED: Electroplating, surface rust, and mild pitting are removed. Metal is soaked and cleaned. Knurling is cleaned with a wire brush wheel to avoid "dulling" of the knurling detail.

- GRIPS STRIPPED AND REFINISHED: Wood grips are stripped and at least two coats of gun stock oil are applied. Resin grips are cleaned and polished.

- CHUCK DISASSEMBLED, INSPECTED, AND CLEANED: Chuck parts are inspected for excessive wear and replaced if worn. All parts are soaked in solvent, hand cleaned, then lightly lubed. Chuck is reassembled, polished, and packed with grease.

- PAWLS, JAWS,AND RETAILER NUT ARE GUN BLUED: While the chuck/pawl shaft is being restored, pawls, jaws and the retainer nut (on Stanley braces) are cleaned and gun blued.