Gallery

Full Description

Customer Reviews

Sorry, our agreement with Woodcraft restricts us from shipping WoodRiver Planes to the U.S.

I own and recommend WoodRiver V3 planes. These planes are based on the reliable Stanley Bedrock design, are very well made, and have an excellent price point making them a "BEST VALUE."

All of our WoodRiver bench planes receive our Cosman preparation service so they are 100% ready to use out of the box. See prep service below for description of what we do.

Traditionally, a smoothing plane is the last plane used on a wood surface. When sharpened and used properly, it produces a finish that surpasses that made by sandpaper.

Because I keep my jack plane freshly sharpened I normally don’t need to use a smoother, but on those occasions when I do, I reach for my WoodRiver No. 4-1/2.

I think the No. 4 is useful for folks with very small hands and low body weight that would find a No. 4-1/2 too big or heavy to use.

-

No. 4 Plane size: 2-7/16” wide x 9-7/8”long with 2”wide blade.

- Includes our Plane Preparation Service.

- Heavy, stress-relieved ductile iron castings.

-

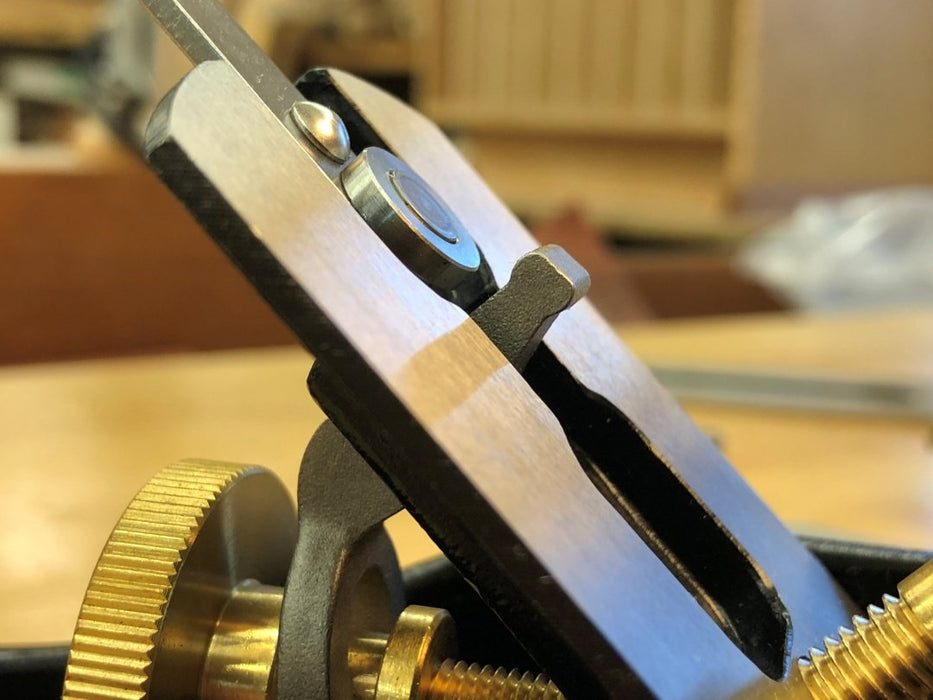

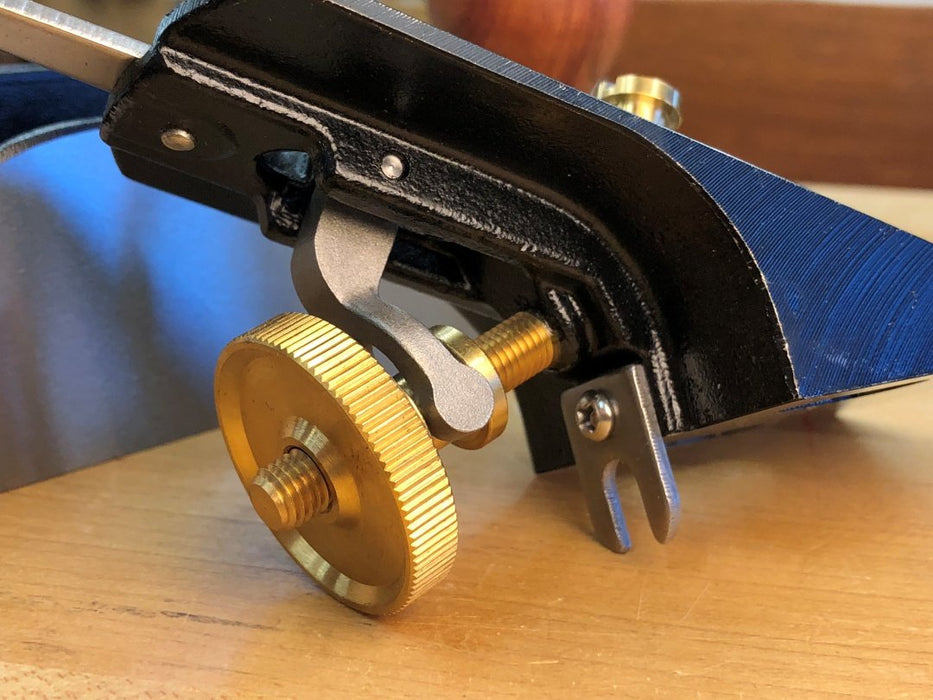

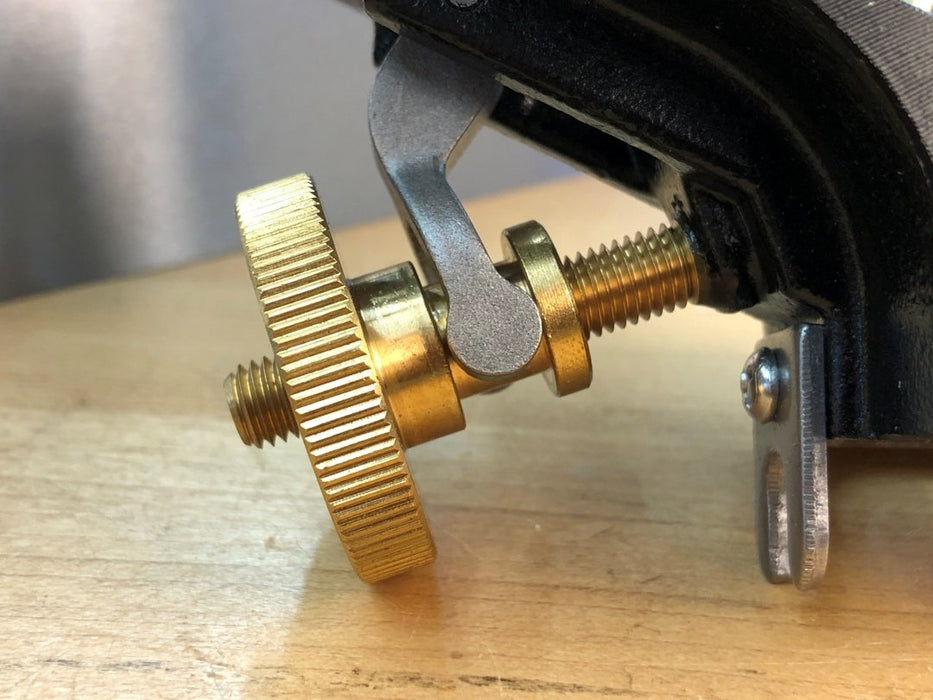

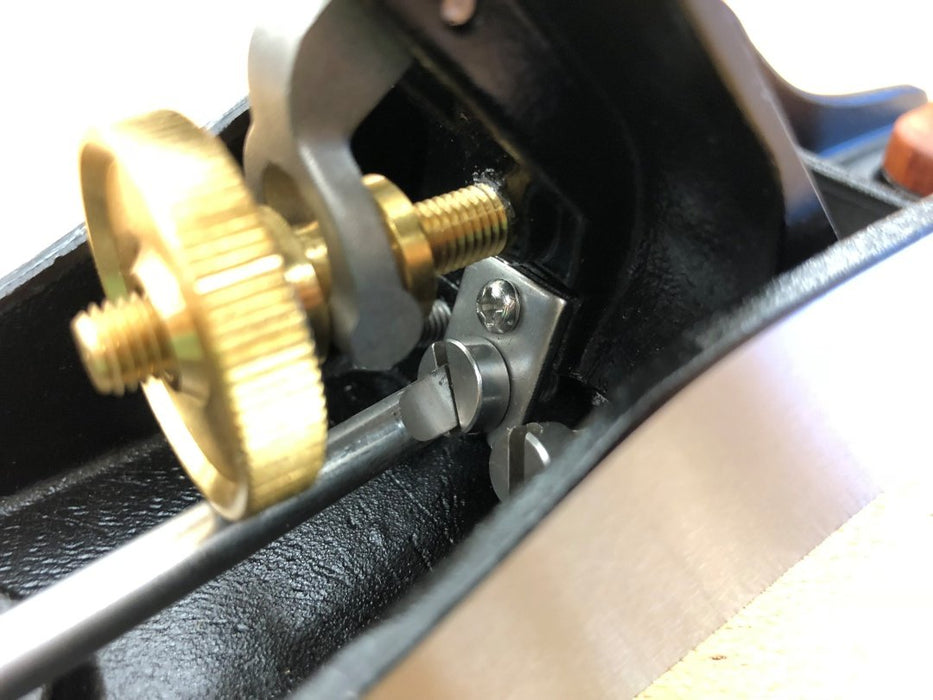

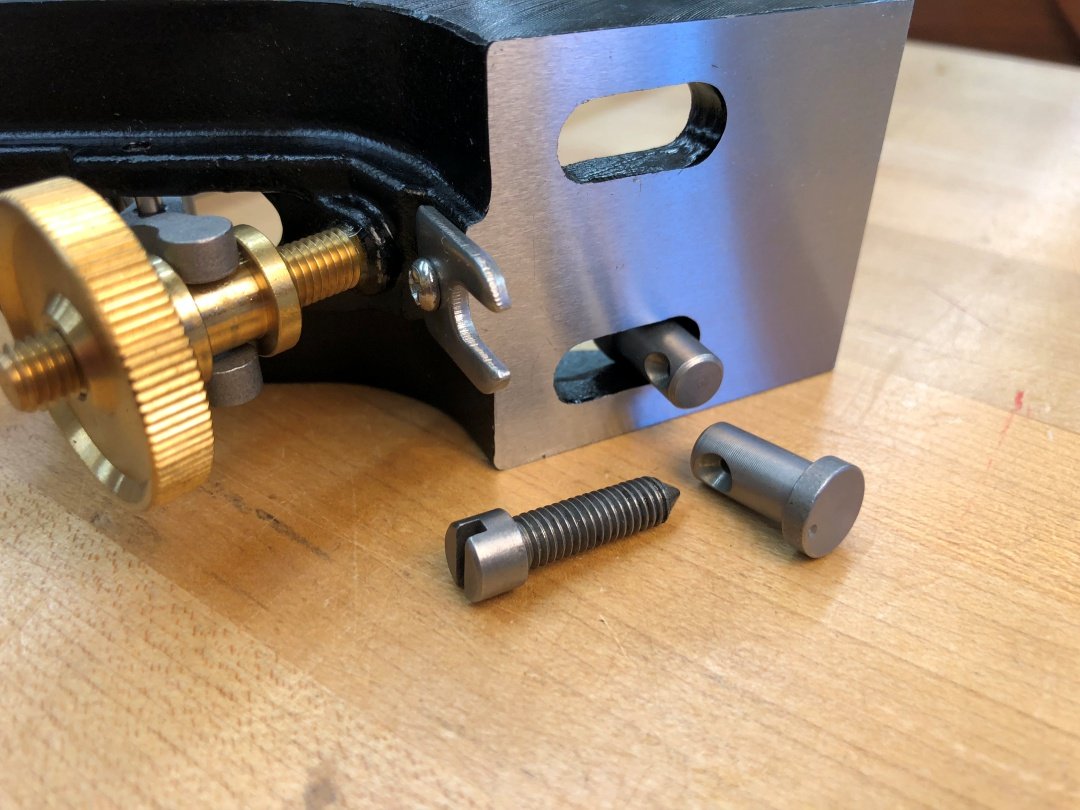

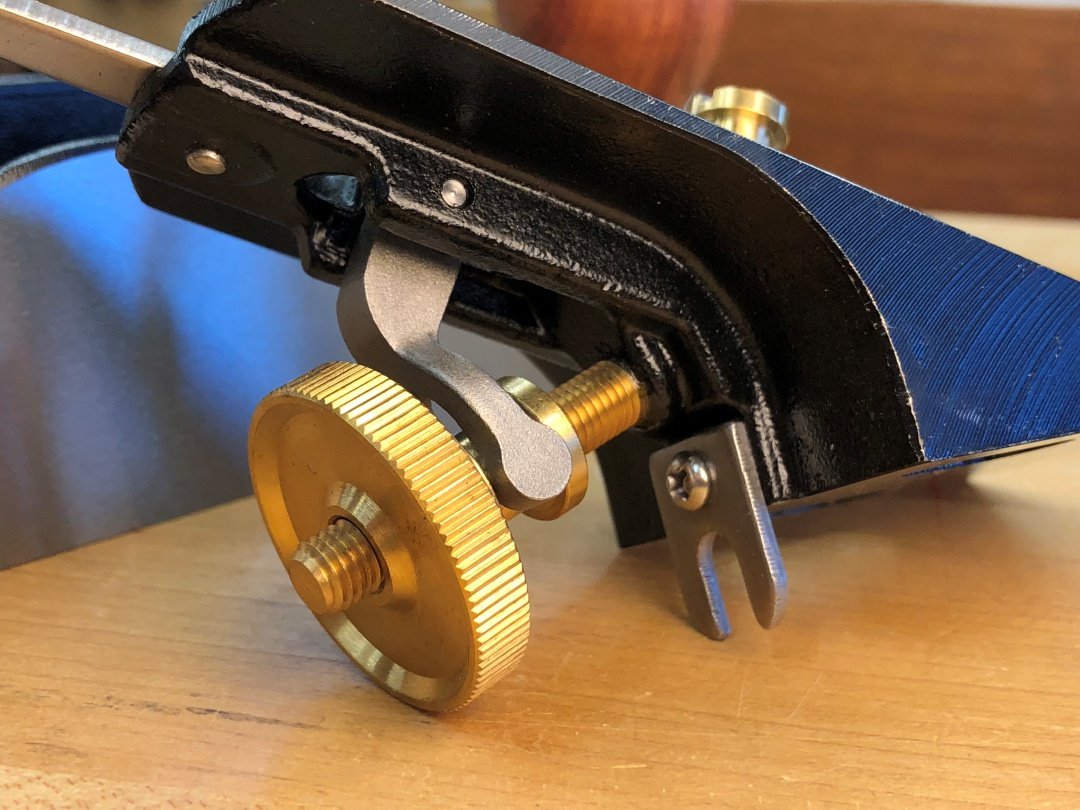

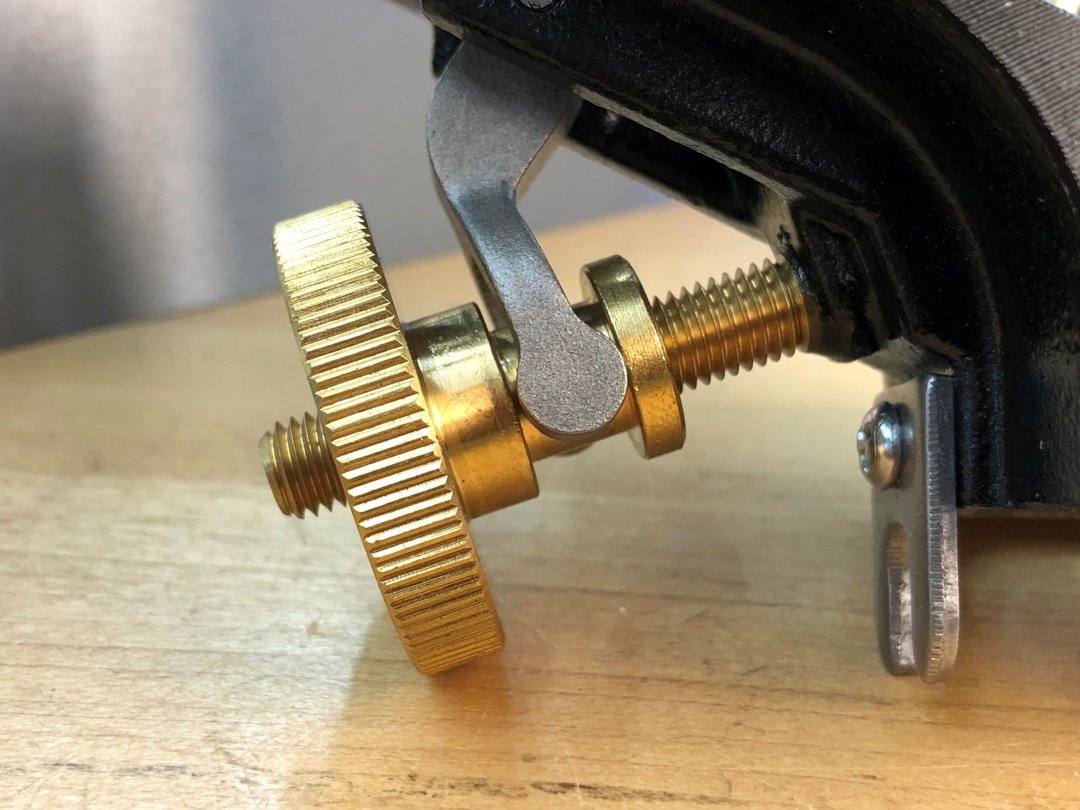

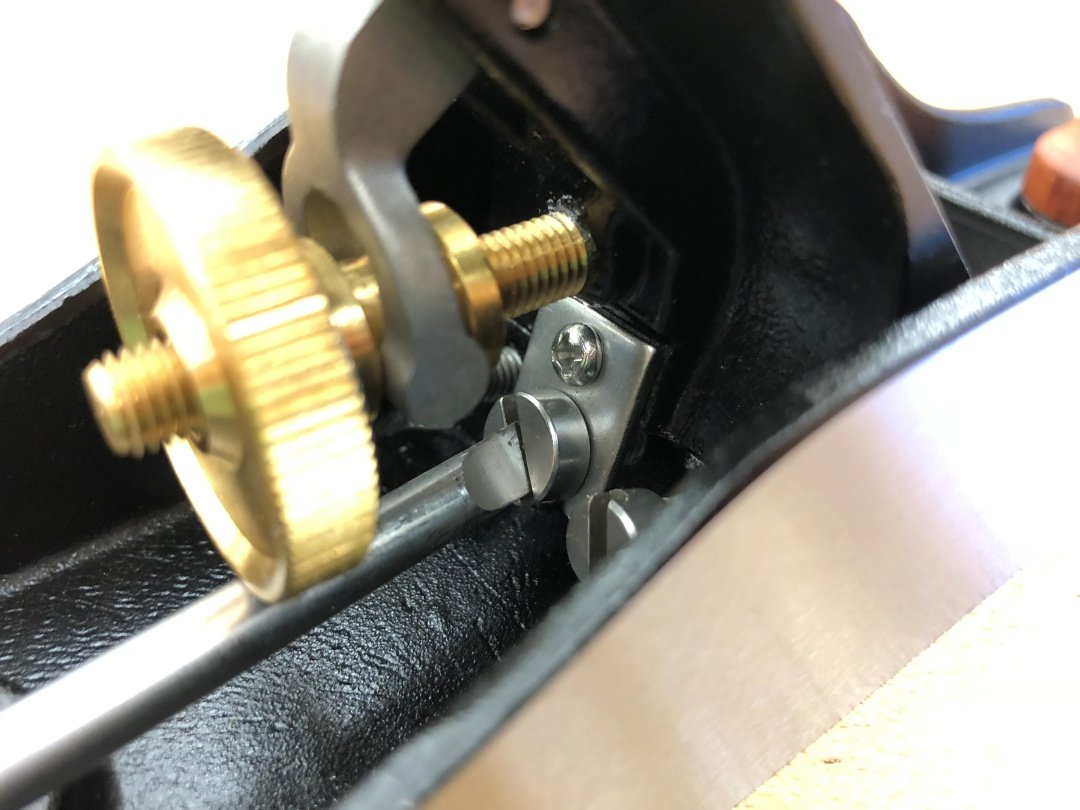

Fully machined adjustable frogs bedded at a 45 degree angle.

-

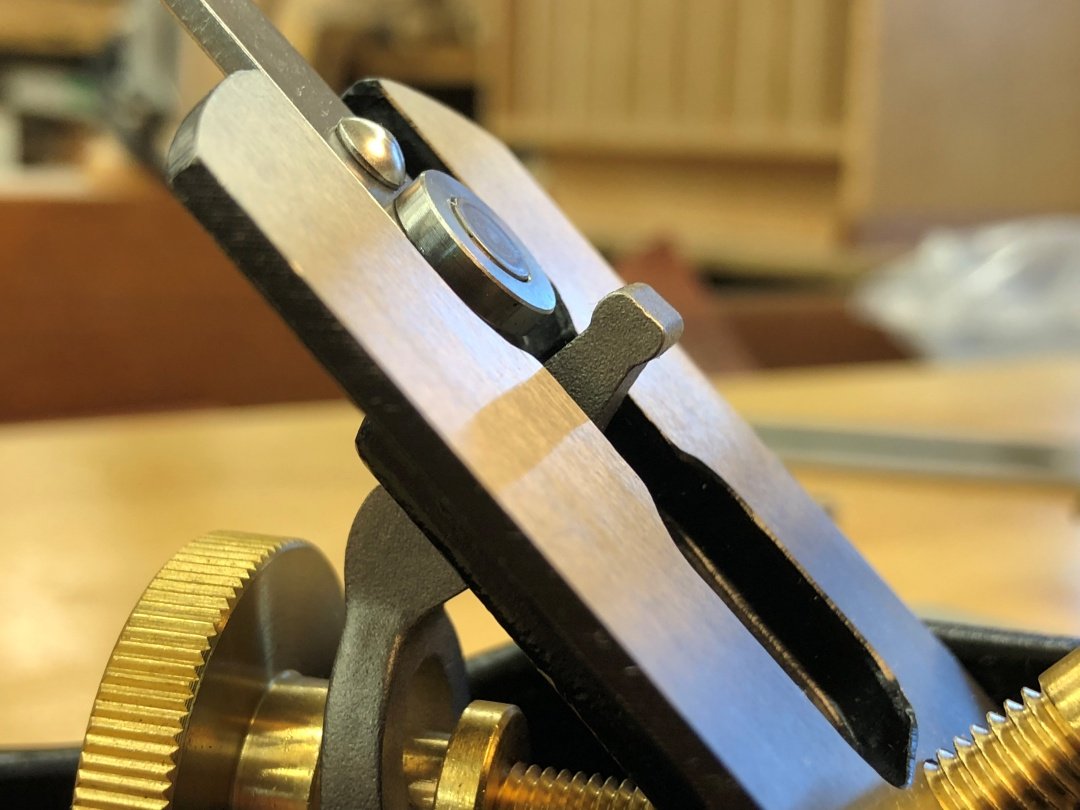

Thick steel blade and chipbreaker dampens vibration making solid planing.

-

Lightly finished Bubinga handles provide comfort and control.

-

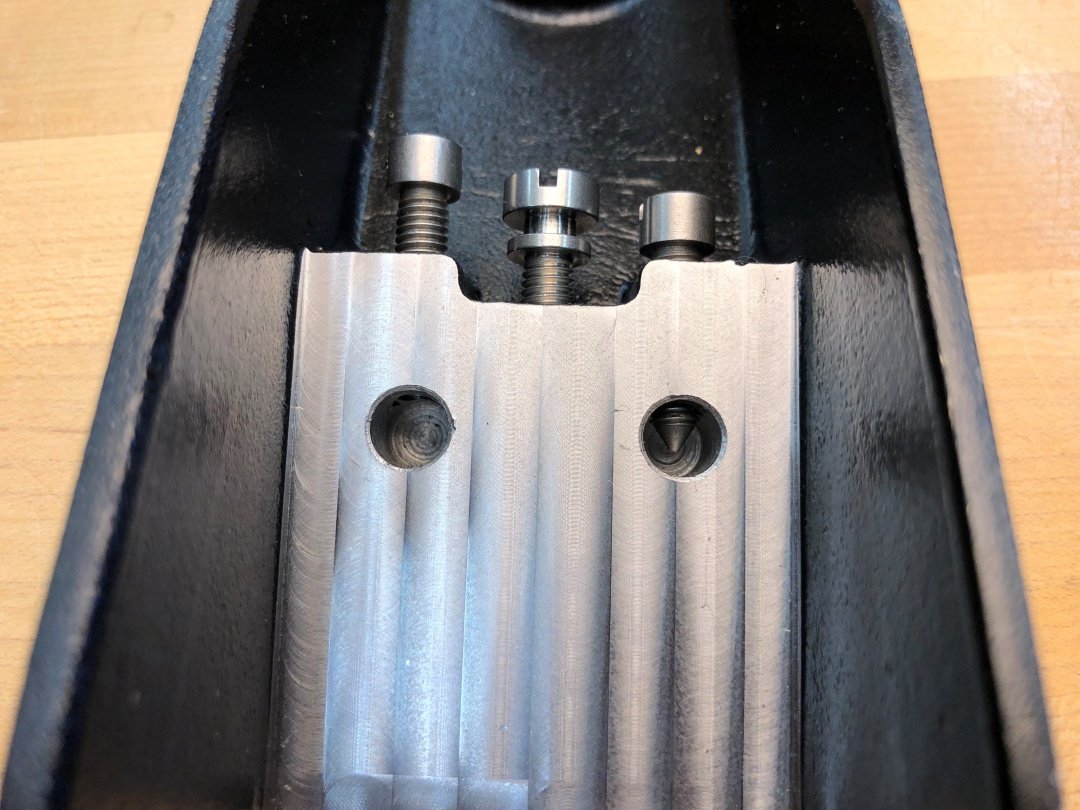

Soles and sides are machined flat and square within tightly held tolerances.

Plane Preparation Service. All planes require some preparation. Our complete plane preparation service makes it so that no set-up is required by you. Your plane will be ready to use 'out-of-the-box! Our Plane Preparation Service includes:

- Flattening the sole to within +/- 0.0015 of an inch (0.038mm) of perfectly flat.

- Squaring the sides to within +/- 0.0015 of on inch (0.038mm) of 90 degrees to the now flat sole.

- Flattening the bottom of the the rear handle (tote) and the front handle (knob) and their boss so they mate properly with no movement.

- Chamfering / easing all edges and corners on the sole of the plane.

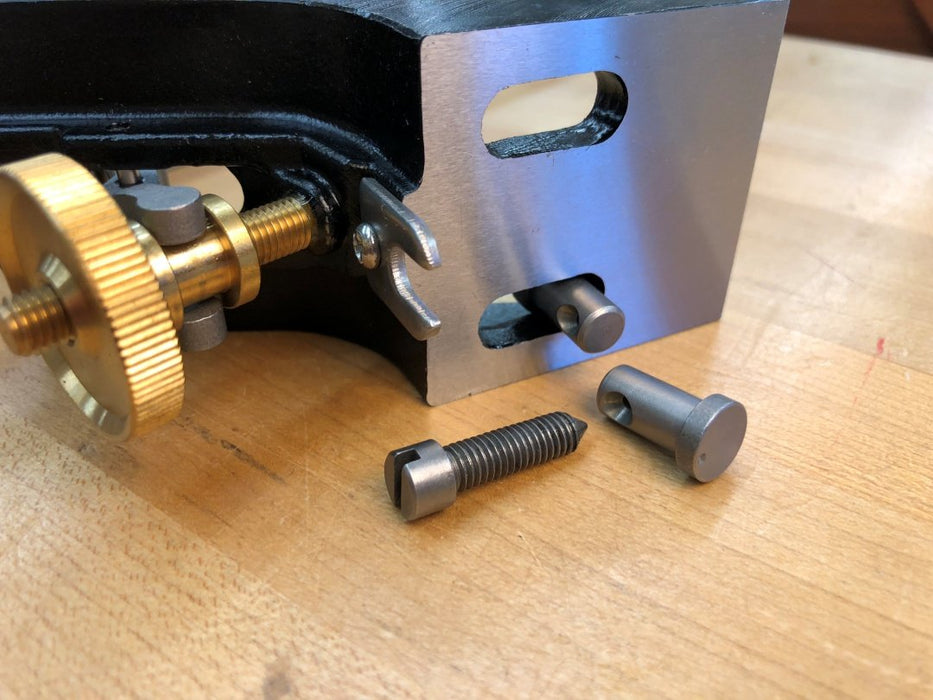

- Tuning the lateral adjustment lever so it moves freely.

- Applying a back bevel (Charlesworth ruler trick) to the back of the plane blade.

- Sharpen the blade using micro-bevels. Final polishing is done using 16,000 grit ceramic waterstone.

- Flattening the back edge of the lever cap so it mates properly to the chipbreaker.

- Flattening the leading edge of the chipbreaker so it mates properly to the blade.

- Testing the plane for proper operation and set-up.

- Removing all of the shipping / packing grease and applying a light coat of camellia oil to all the metal surfaces to prevent rust.

Which Plane?