Gallery

Full Description

Customer Reviews

KITs

Every woodworker should have at least one shoulder plane in their tool kit. Shoulder planes are indispensable for trimming dados, grooves, rabbets, tenons, and shoulders. A shoulder plane is also one of the quickest ways to eliminate the marks left by a saw blade (machine or hand) and to fine-tune your joints.

WoodRiver Shoulder Planes are very well made, and have an excellent price point making them a "BEST VALUE". They are a real treat to use and I highly recommend them.

The heft of the tool, the way it fits the hand, and the tight mouth enable me to make precisely controlled cuts. I really like the sensitive, easy to manipulate blade adjuster. Normally I have it set to take thin finishing cuts. But, as needed, I can fairly quickly readjust the blade for a more aggressive cut. And, the cuts are completely chatter-free, regardless of the type of wood I'm working with.

WoodRiver shoulder planes are available in three sizes: No. 91 (Small), No. 92 (Medium) and No. 93 (Large). If you are just starting out or are limited on funds I recommend the No. 92 (Medium) as your first shoulder plane

-

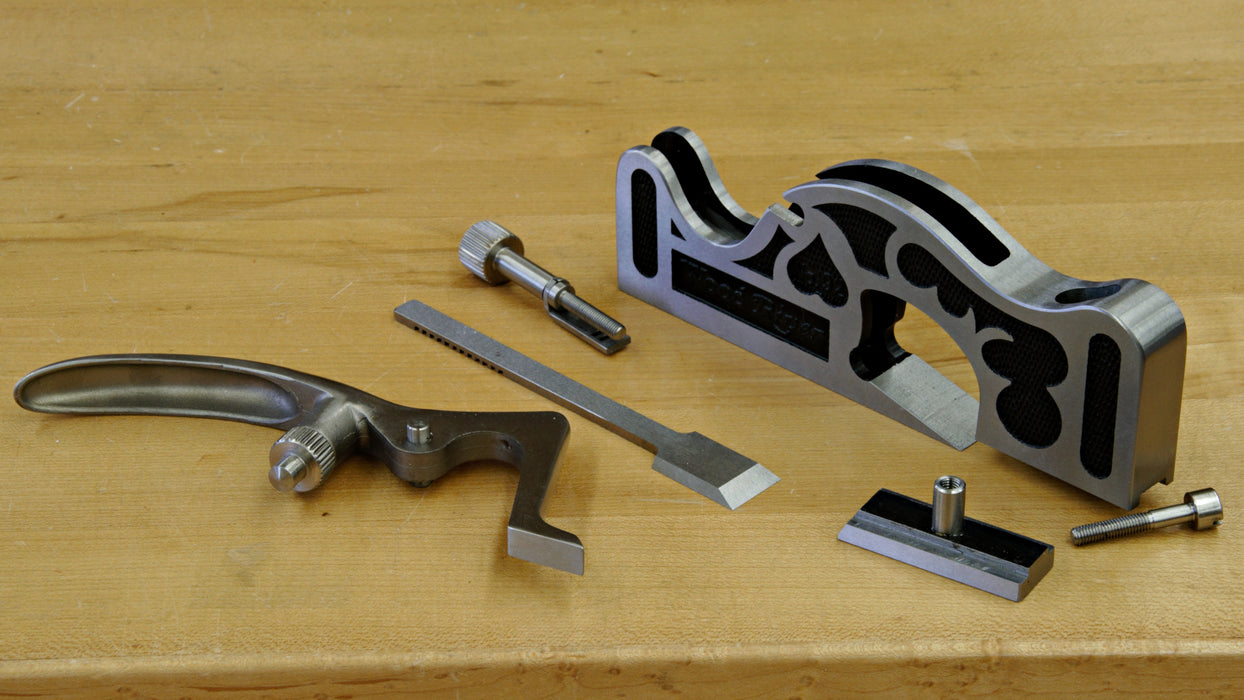

Modeled after Edward Preston and Sons’ classic shoulder plane design.

-

The classic shoulder plane features were retained – narrow body, slightly proud blade (to clean corners), sides square to the sole, flat bottom and a necessary robustness.

-

Dimensions: Body length 81/4", width 1", height 3”; Overall Plane length 10-7/16", height 3-7/8"; weight: 3 lbs., 12.8 oz.; bedded angle, 15°; blade angle 25°.

-

A major new feature was added, an adjustable toe used to control the throat opening and help to minimize tear-out on end grain.

-

The body is Cr40 stress-relieved ductile steel.

-

The lever cap is made from SUS 304 stainless steel, which has nickel and chromium added for superior corrosion resistance.

-

Blades are Mn65 tool steel hardened to HRC60-64 which combines toughness with the ability to take a keen edge.

PRODUCT DETAILS

Overall. Cast from Cr40 ductile iron, a strong, durable alloy with good wear resistance. After casting, the body is stress-relieved to minimize the likliehood of warping, ensuring that the sole remains flat. The plane bed has a 15-degree angle, while the blade is ground at a 25-degree angle, giving an effective cutting angle of 40-degrees. It's a good compromise angle for working with either long, cross, or end grain. Of course, you can easily change the effective cutting angle by regrinding the blade bevel, or better yet, purchasing a replacement blade and regrinding the bevel.

Controls. The controls on the WoodRiver Shoulder Planes are quite simple. Turn a spinwheel to remove, the lever cap; turn an adjuster at the back of the plane to advance or retract the blade; and, loosen a screw on the top of the plane to move the shoe that controls the throat opening. Certainly nothing new here, but everything works smoothly, like butter on toast.

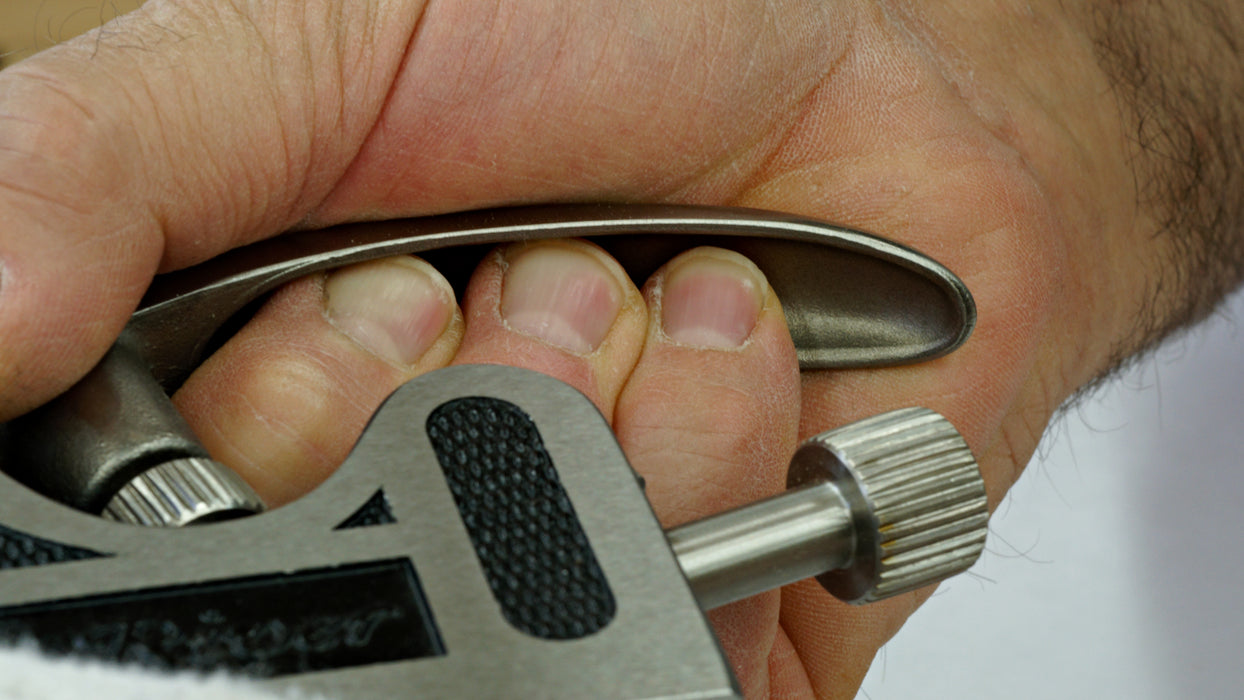

Finish. Not only is the fit and finish on the plane superb, but the decorative detailing harkens back to the glory days of plane making. The plane not only looks appealing, it feels great in the hand. The rounded over edges and the textured recesses milled into the sides make it easy to grip and comfortable to hold.

Shape. There's a gentle curve on the top of the plane, just behind the mouth plate retaining screw, which makes a natural resting place for the forefinger when pushing the plane. The palm of your hand is then supported by the long swooping lever cap. Sometimes you might want to pull the plane into your work, in which case your forefinger can rest on the lever cap and the palm of your hand will sit nicely in that curve near the retaining screw.

Lever Cap. The lever cap is made from SUS 304 stainless steel, which has nickel and chromium added for superior corrosion resistance. The lever is nicely proportioned in relation to the overall length of the plane. A few turns of the spinwheel relieves tension so that you can adjust the position of the blade, or remove the lever cap entirely if you need to extract the blade. The toe is perfectly flat and provides even pressure across the blade, helping to reduce chatter.

Blade Adjuster. The Norris-style blade adjuster is attached to a captive nut that slides along a track in the plane body. Two spurs on the nut engage the slots on the back of the blade, enabling you to move the blade in precise increments. With a bit of practice you'll get a feel for how much you need to turn the knurled adjuster knob to alter the blade position. I found the adjustments to be very smooth and precise with just the slightest amount of backlash. However, you do need to be careful that the blade doesn't wander to the left or right as you adjust its position - otherwise the edge of the blade won't be flush with the mouth of the plane.

Blade. The blade is made of Mn65 (ASTM 1566) high carbon tool steel hardened to Rockwell 60-64. Mn65 is similar to A2 tool steel, but it has somewhat less wear resistance. The blade comes nicely sharpened and the back flat. The blade projects about .003" beyond each side of the body. This provides the clearance necessary to make clean, square cuts.

Throat. As on any hand plane a narrow mouth helps minimize tear-out. On the Wood River there is a screw located on the top edge of the plane that locks the shoe in place. Once the screw is backed out you can easily reposition the shoe, and then re-tighten the screw. For thinner cuts tighten up the throat; for thicker cuts open it up to prevent wood shavings from clogging the mouth.When making throat adjustments I found that it's best not to back out the screw too much, just enough so that you can push the shoe forward or pull it backwards. This way you can make suprisingly precise mouth adjustments. As well, there's no need to over tighten the screw - moderate hand pressure is all it takes.

Flat & Square. I checked for flatness and squareness fore and aft of the mouth, and found the sole to be precisely ground and absolutely flat, with the sole perfectly square to the sides, a critical feature if you intend to have crisp, square corners.